Disposable — Coveralls

-

-

• Protective coverall CE Type 5 & 6

• 50gsm

• For fine dust particles

• Reduced spray and limited splash

• 2 way zip front with adhesive storm flap

• Elasticated cuffs, ankles, waist and hood

• Breathable fabric

• Ideal for hazardous waste removal

• Individually packaged

• Very economical

• Conforms to:

EN ISO 13688:2013+A1:2021

EN ISO 13982-1:2004+A1:2010 (Type 5)

EN 13034:2005+A1:2009 (Type 6)

EN 1073-2:2002 (Class 2)

EN 1149-5: 2018

EN 14325:2004• Protective coverall CE Type 5 & 6

• For fine dust particles

• Reduced spray and limited splash

• 2 way zip front with adhesive storm flap

• Elasticated cuffs, ankles, waist and hood

• Breathable fabric

• Ideal for hazardous waste removal

• Individually packaged

• Very economical

• Conforms to:

EN ISO 13688:2013+A1:2021

EN ISO 13982-1:2004+A1:2010 (Type 5)

EN 13034:2005+A1:2009 (Type 6)

EN 1073-2:2002 (Class 2)

EN 1149-5: 2018

EN 14325:2004• Protective coverall CE Type 5 & 6

• For fine dust particles, reduced spray and limited splash

• Anti static

• 2 way zip front with storm flap

• Elasticated cuffs, ankles, waist and hood

• Microporous breathable fabric

• Individually packaged

• Very economical

• Conforms to:

EN ISO 13688:2013+A1:2021

EN ISO 13982-1:2004+A1:2010 (Type 5B)

EN 13034:2005+A1:2009 (Type 6B)

EN 1073-2:2002 (Class 1)

EN 14126:2003+AC:2004

Resistance to Penetration by contaminated liquids under hydrostatic pressure = Class 6

Resistance to Penetration by infective agents due to mechanical contact with substances containing contaminated liquids = Class 6

Resistance to penetration by contaminated liquid aerosols = Class 3

Resistance to penetration by contaminated solid particles = Class 3

EN 1149-5: 2018

EN 14325:2004Microporous type 3/4/5/6 disposable coverall

• 90gm 56% SMS polypropylene, 44% polyethylene

• Polyethylene laminated +3 layers of polypropylene

• Ultrasonic taped seams

• Elasticated hood, wrists, ankles and waist

• Zip front with storm flap

• Elasticated thumb loops

Ideal uses:

• Maintenance & Repair

• Powder coating

• Insulation laying

• Pharmaceutical manufacture

• Paint spraying

• Wood & Metal processing

• Low level chemical handling

• Resin application

• Pressure/Steam water cleaning

• Fibreglass manufacture

• Conforms to:

EN ISO 13688:2013+A1:2021

EN 14605:2005+A1:2009 (Type 3B & 4B)

EN ISO 13982-1:2004+A1:2010 (Type 5B)

EN 13034:2005+A1:2009 (Type 6B)

EN 1073-2:2002 (Class 2)

EN 14126:2003+AC:2004

Resistance to Penetration by contaminated liquids under hydrostatic pressure = Class 6

Resistance to Penetration by infective agents due to mechanical contact with substances containing contaminated liquids = Class 6

Resistance to penetration by contaminated liquid aerosols = Class 3

Resistance to penetration by contaminated solid particles = Class 3

EN 1149-5: 2018

EN 14325:2004• Fabric disposable boilersuit

• Non woven fabric

• 33gsm SMS (spunbond + meltblown + spunbond nonwovens)

• Elasticated hood

• Elasticated waistband and ankles

• No.3 nylon spiral one-way zip front opening

• Zip colour matches garment shell fabric.• Fabric disposable boilersuit

• Non woven fabric

• 33gsm SMS (spunbond + meltblown + spunbond nonwovens)

• Elasticated hood

• Elasticated waistband and ankles

• No.3 nylon spiral one-way zip front opening

• Zip colour matches garment shell fabric.• Non woven polypropylene

• Disposable visitors coat with collar

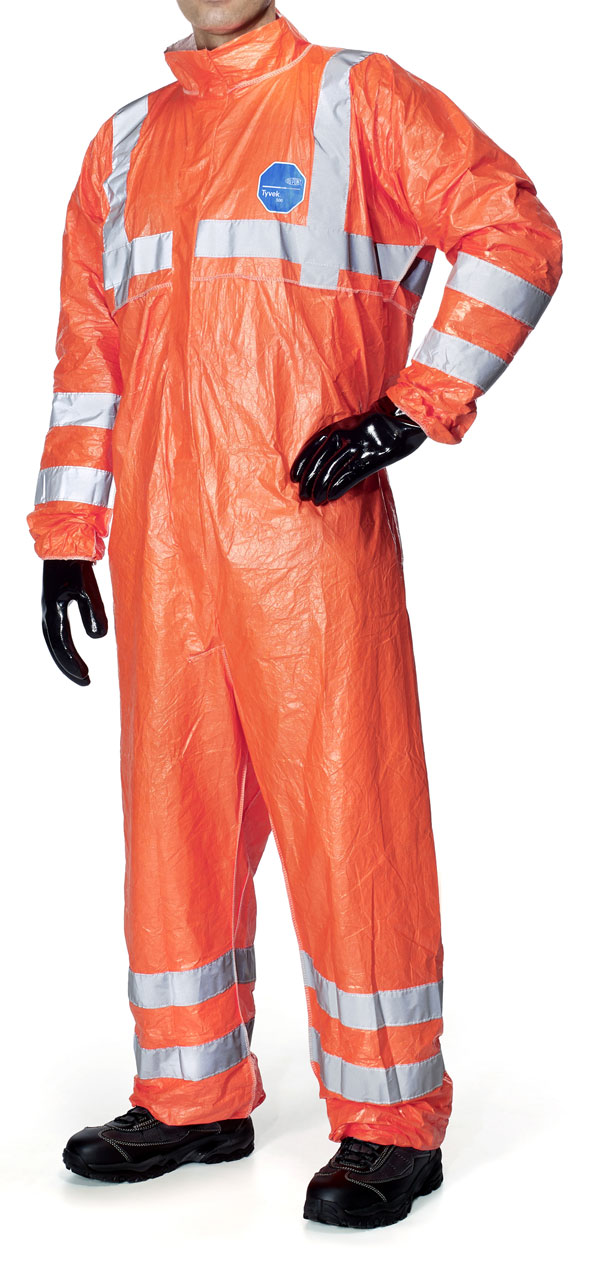

• Hook and loop fasteningTyvek® 500 HV garments are mainly composed of flash spun polyethylene, providing an ideal balance of protection, durability and comfort. Thanks to their nonwoven structure, they are permeable to both air and water vapour, yet repel water-based liquids and aerosols. They offer an excellent barrier against fine particles and fibres, are ultra-low linting and antistatically treated on the inside. Their bright fluorescent orange colour combined with silver grey retroreflective bands make them highly visible during the day as well as in the night (when exposed to a light source).

Applications for Tyvek® 500 HV garments include rail, road, mining, waste handling, undergrounds, ports, airports and construction.

•DuPont™ Tyvek® 500 HV TY127S XG Hooded ergonomic-protective design

• All-in-one solution: high-visibility (to the highest class), chemical, biological and antistatic protections in one coverall

•hood designed to fit a respirator

• Retroreflective bands create a symmetric "X" on the back of the coverall distinguishing rearward and forward orientation of the wearer.

•additional bands above the elbows, wrists, knees and ankles for added protection

•Large, easy-grasp auto-lock zipper puller made with Tyvek® material, Tyvek® flap.

•robust yet lightweight with good freedom of movement

•Elasticated wrists, ankles and waist

• Very low inward leakage thanks to optimised design

•stitched external seams

•Chemical protective clothing, Category III, Type 5-B and 6-B.

• Antistatic treatment (EN 1149-5) - on inside

•EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination).

•EN ISO 20471 (High Visibility Clothing, Class 3), RIS-3279-TOM Issue 2Workers operating with full-body harness in environments where hazardous particle or light liquid aerosol hazards are present, previously had to compromise between efficient personal protection• and protecting their full-body harness against external contamination.

The new Tyvek® 500 HP TY178S HP garment offers a unique solution - protection of both the wearer and the full-body harness - by providing a barrier between the user and the particle or light liquid aerosol hazards• in the environment. Designed to be worn over a full-body harness, the innovative, patent-pending garment design allows workers to access and utilize multiple D-Rings on their full-body harness while providing an ideal balance of protection, durability, and comfort.

This new TY178S HP model has four attached sleeves for use with front, back and side D-Rings of a full-body harness. The off-centered zipper entry allows accommodating the front D-Ring sleeve for front D-Ring connection. Compatible with variety of full-body harness models, this garment may be used for a wide range of applications including painting, cleaning, maintenance, and more.

In addition to its innovative design, this garment also offers an ideal balance of protection• and durability thanks to the unique Tyvek® fabric. It is also extremely lightweight offering high level of comfort and mobility. The garment is low linting (suitable also for paint applications). Silicone non-added.

•multiple access points to the full-body harness through the four elasticized D-Ring Sleeves that are attached to the garment

•off-centred zipper entry to accommodate the front D-Ring Sleeve for front D-Ring Connection

ו-Piece Hood with elastic face opening

•Stitched Seams

•Tyvek® thumb loops

•Tyvek® zipper and Tyvek® storm flap

•Elasticated ankles & wrists and elasticated (glued-in) waist

•Chemical protective clothing, Category III, Type 5-B and 6-B

•EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination).

•Antistatic treatment (EN 1149-5) – on both sides of the fabricThe 4520 is made from extremely lightweight and breathable material and is designed to offer protection against hazardous dusts and limited liquid splashes.

• Elasticated hood, ankles and waist.

• 2 way zip with sealable tab on storm flap.

• 3- panel hood.

• Knitted cuffs.

• Low linting.The 3M 4530 is designed to be lightweight and breathable whilst offering protection against hazardous dusts and limited liquid splashes. The material complies with ISO 14116:2008 for limited flame spread index 1 (must be worn over an index 2 or 3 garment).

Type 5/6

Elasticated hood, ankles and waist

2 way zip with fully sealable storm flap 3-panel hood Knitted cuffs Low linting• Highly breathable, antistatic suit used stripping, clear up or handling of asbestos, general maintenance, construction and contract cleaning

• 3-piece hood

• Elasticated hood, wrists, waist and ankles

• 2-way front zipper with re-sealable storm flap

• Finger loops

• Anti-static treatment

• Conforms to Type 5, 6, EN1073-2 and EN1149-5• Provides both protection and comfort with exceptional liquid and particle protection

• 3-piece hood

• Elasticated hood, wrists, waist and ankles

• 2-way front zipper with resealable storm flap

• Finger loops

• Conforms to Type 5, 6, EN14126, EN1073-2 and EN1149-5• White, Hooded coverall

• Type 5/6

• Stitched internal seams

• Elasticated wrists, ankles, and face

• Elasticated waist (glued-in)

• Zipper flap

CAT III

EN ISO 13982-1:2004 + A1:2010

EN 13034:2005 + A1:2009

EN 1073-2:2002

EN 1149-5:2018 (on inside)• White, hooded coverall 3 piece hood.

• Elasticated face, wrist and ankles.

• Protection against particles and liquid splash.

• Must be worn over the top of a primary FR garment.

• Stitched external orange seams.

• Suitable for petrochemical, railway, welding and many other applications.

• Conforms to: CAT III, Type 5,6. EN 1073-2, EN 1149-5, EN 14116 Index 1

EN13688 - general performance requirements for ergonomics.

EN13982 - Type 5 test

EN13034 -Type 6 test

EN14325 - CE marking - protective clothing• Tyvek® 500 HV

• Flourescent Orange, collared coverall

• Robust, yet lightweight

• HV reflective bands

• Elasticated waist, wrists and ankles

• Excellent barrier to fine particles and fibres

• High Visibility that doesn't wash out

• Suitable for working in rail, mining,road, underground, waste, ports , airports and many other applications.

• Conforms to: CAT III, Type 5B, 6B. EN1073-2, EN1149-5 (inside), EN14126, EN ISO 20471 class 3/3

• Pictograms: CAT III, Type 5B, 6B. EN1073-2, EN1149-5 (inside), EN14126, EN ISO 20471 class 3/3

• RIS-3279-TOM Issue 1• White, hooded coverall

• Attached socks and boot flaps

• Stitched and over taped seams

• Thumb loops

• Tunnelled elastication at wrists, ankles, and face

• Elasticated waist (glued-in)

• Tyvek zipper

• Self-adhesive zipper and chin flap

CAT III Type 4-B, 5-B, 6-B

EN 1073-2:2002

EN 14605:2005 + A1:2009

EN ISO 13982-1:2004 + A1:2010

EN 13034:2005 + A1:2009

EN 14126:2003

EN 1149-5:2008Tyvek ® 800J

• White, hooded coverall

• Robust, yet lightweight

• Adhesive Chin Flap

• Elasticated face, wrist and ankles

• Thumb Loops

• Self-Adhesive Zipper Flap

• Stitched and over taped seams

• Effective Barrier for low concentrated water based inorganic chemicals and hazardous particulates

• Oil repellancy

• Suitable for industrial cleaning, petrochemical, sewers and maintenance and many other applications.

• Conforms to: CAT III, Type 3B, 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• Pictograms: CAT III, Type 3B, 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126• Hooded coverall.

• Robust, yet lightweight.

• 3 piece hood.

• Elasticated face, wrist and ankles.

• Excellent barrier to fine particles and fibres.

• Ultra-low linting.

• Stitched external seams.

• Suitable for pharmaceutical, chemical processing, oil and gas industry, maintenance spray painting and many other applications.

• Conforms to: CAT III, TYPE 5B, 6B. EN 1073-2, EN 1149-5, EN14126Tyvek ® Classic Plus

• White, hooded coverall

• Robust, yet lightweight

• Adhesive Chin Flap

• Elasticated face, wrist and ankles

• Thumb Loops

• Excellent barrier to fine particles and fibres

• Stitched and over taped seams

• Ultra-Low Linting

• Suitable for Pharmaceutical manufacturing, nuclear, laboratory, biohazards and many other applications.

• Conforms to: CAT III, Type 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• Pictograms: CAT III, Type 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• EN 14605:2005 + A1:2009

• EN ISO 13982-1:2004 +A1:2010

• EN 13034:2005 + A1:2009Tyvek® 500 Xpert

• White, Hooded coverall

• Ergonomic-protective design

• Stitched external seams

• Elasticated wrists, ankles and face

• Elasticated waist (glued-in)

• Tyvek® zipper and flap

• Conforms to: CAT III, TYPE 5B, 6B. EN 1073-2, EN14126, EN 1149-5 (on both sides)• Hooded coverall

• Lightweight and durable (<700g)

• Adhesive chin flap

• Elasticated face, wrist and ankles

• Thumb loops

• Double cuffs, zippers and zip flaps

• Stitched and over seams

• Good barrier against organic and inorganic chemicals

• Suitable for oil and gas industry, chemical engineering, response teams and many other applications

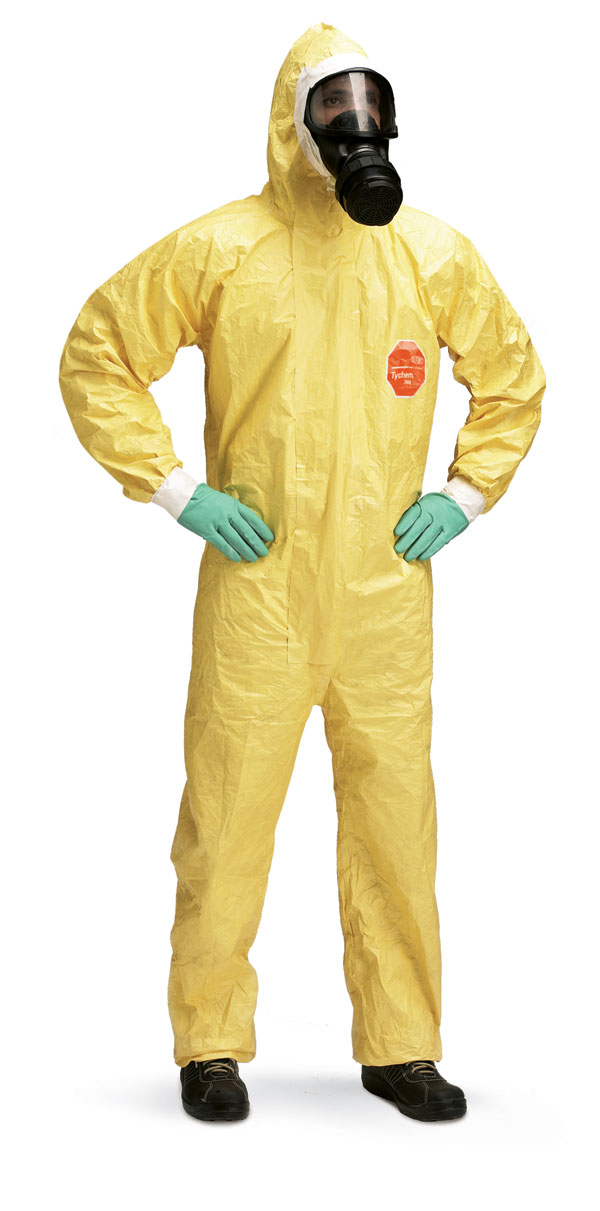

• Conforms to: CAT III, Type 3B, 4B, 5B, 6B, EN 1073-2, EN 1149-5, EN14126DuPont Tychem® C, model CHA5. Hooded coverall.

Available in bright yellow for high visibility.

• Elasticated face, wrists, waist and ankles for an optimal fit, thumb loops prevent sleeves from riding up.

• Self-adhesive chin flap for tight seal of suit to face-masks.

• Made from a lightweight and durable fabric (<450g per garment).

Tychem® C garments utilise the strength of Tyvek® and a polymeric barrier coating to offer good permeation barrier protection against a wide range of inorganic chemicals and biological hazards (even under pressure).

Tychem® C is used for splash or pressurised splash protection in a variety of industrial environments, including pulp and paper manufacturing, food processing, chemical processing and pharmaceutical manufacturing.

Chemical protective clothing, Category III, Type 3-B, 4-B, 5-B and 6-B

EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination)

Antistatic treatment (EN 1149-5) - on inside

Stitched and over-taped seams with barrier tape for protection and strength.

Self-adhesive double zipper flap closure system for higher protection.• Made from lightweight durable fabric.

• Offers chemical premeation protection to an extensive range of chemicals, highly concentrated inorganic chemicals, paticulates, biohazards and certain chemical warfare agents.

• Stitched and over-taped seams with barrier tape for protection and strength.

• Self-adhesive double zipper flap closure system for higher protection.

• Chemical protective clothing, category III, Type 3-B, 4-B, 5 + 6.

• EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination)

• Anti-static treatment (EN 1149-5) - on inside

EN 1073-2:2002

EN 14605:2005 + A1:2009

EN ISO 13982-1:2004 + A1:2010 (Type 5)

EN 13034:2005 + A1:2009 (Type 6)

EN 14126:2003

EN 1149-5:2008-

24 Products

-

With over 20,000 products in stock at our warehouse, our team are here to help & find you the right product.

- Switchboard +44(0)121 524 2323

- Sales Hotline +44(0)121 524 2300

- Sales sales@beeswift.com

- Export export@beeswift.com